|

Broadband,Inc.

〒121-0832

東京都足立区

古千谷本町4-7-9

お問い合わせ

TEL:03-5838-0082

ask@bblaser.com |

| |

|

|

●

結晶オーブン&温調器 |

|

|

|

Abal

OptoTek社 (AOTK)

|

|

|

|

精密結晶オーブン&温度コントローラー

We

provide specially design precision crystal

oven and temperature controller to install,

heat and stabilize crystal to a certain

temperature. In response to the demand of

precision crystal oven and temperature

controller,and the trend of miniaturization of

optical devices, AOTK now introduces our

second generation of crystal oven and

temperature controller.

Precision

Crystal Oven Specifications

|

|

OTC-I |

OTC-II |

|

Host

Crystal Size

|

up

to 7mm×7mm×25mm

|

up

to 6×6×35mm |

|

Oven

size |

Φ32mm

x 38.1mm (1.5")

|

Φ55mm

x

60mm

|

|

Temperature

Range

|

Room

Temperature to 220°C

|

Room

Temperature to 160°C |

|

Accuracy

|

0.1°C

|

|

Weight

|

105g

|

300g |

|

Power

Consumption |

15W/110VAC

or 15W/220VAC

|

20W/110VAC

or 20W/220VAC |

|

Connector

|

4-pin

audio plug

|

|

Cable

|

4

lines cable about 1 meter

|

Option:

Oven can be added windows on both end faces

The

crystal oven has a small footprint which

allows the oven to be mounted on standard

1" optical mounts. This is very

important for quick experiments where

limited space and time do not allow

specially designed mechanical part to fit

in. It also saves precious time and money

for product development.

Temperature Controller Specifications

The

temperature controller is microprocessor

controlled, and has dual line 4 digits LED

display (set point and real temperature). It

is very easy to operate, and accepts both

110V and 220V power sources.

|

OTC-I |

OTC-II |

| Physical

Size

|

155(L)×105(W)×70(H)mm

|

120(L)×48(W)×96(H)mm |

| Temperature

Range

|

Room

Temperature to 220°C

|

| Warm-up

Time

|

60

minutes

|

| Resolution

|

0.1°C

|

| Stability

|

better

than ±0.1°C

|

| Dissipation

Power

|

<

25W

|

| Power

Consumption

|

<

5VA

|

| Environment

Temperature

|

-10oC

to +55oC

|

| Weight

|

300g

|

400g |

| Set

point range

|

Selectable

|

● Slow

heating rate is suggested for LBO crystal,

in order to prevent coating crack

due to its

inhomogeneous expansion.

Applications

● LBO

NCPM SHG of Nd:YAG/YLF/YVO4

Lasers

● LBO

NCPM OPO Pumped by SHG of Nd:YAG/YLF/YVO4

or Ti:Sapphire Lasers

● KNbO3

NCPM SHG of 860-940nm (a-cut); SHG

990-1070nm (b-cut)

● LiNbO3

NCPM SHG of YAG/YLF/YVO4

● Increase

damage threshold of KTP, LiNbO3

and BBO crystals

● Stabilized

high power SHG, THG, 4HG and 5HG of Nd:YVO4

Application Note

One of the major application of temperature

controlling in nonlinear optical conversion

is to use the Non-Critical Phase-Matching (NCPM)

for some non-linear optical crystals, e.g.

LBO and KNbO3. NCPM is preferred

because it could generate superior beam

quality and efficiency. It has very large

acceptance angle and zero walk-off which are

very important for doubling tightly focused

laser beam or laser beams with large

divergence.

NCPM Applications

| Crystal

|

NLO

Applications

|

Temperature |

| LBO

|

SHG

(I) 1064nm,1053nm,1047nm

SHG (II) 1320nm

|

148°C

- 170°C

40°C

|

| KNbO3

(a-cut) |

SHG

860-940nm

|

20°C

- 180°C

|

| LiNbO3

|

SHG

1064nm |

120°C

|

| KD*P

|

SHG

532nm |

52.1°C

|

| ADP

|

SHG

532nm

|

51.2°C

|

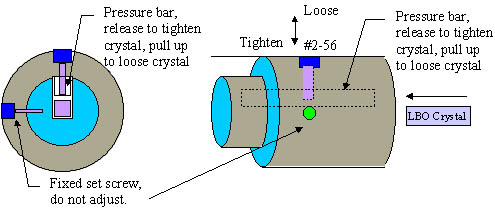

Installation

of Crystals

As

the figure shown above, to install crystal

in the crystal oven:

1

Turn the #2-56 screw on the side of the

crystal oven clockwise to pull up the

pressure bar inside

the crystal oven, until there is enough room

for the crystal.

2. Put the crystal into the oven by sliding

it into the square hole of the crystal

oven. Use wide blade

plastic tweezers to hold the crystal and

push it into the

square hole. Avoid

touching the surface of the crystal clear

aperture at all time.

Put the crystal in the

center of the oven.

3. Turn the same #2-56 screw on the side of

the crystal oven counter-clockwise to

release the pressure bar

inside the crystal oven, after the pressure

bar touches

the crystal top, release

an extra two rounds – this will give

enough force for the

pressure bar to hold the

crystal.

Caution!

●

Do

not try to adjust the fixed setscrew, which

is glued to the crystal oven.

●

Do

not release the pressure bar without the

crystal inside the crystal oven, and

do not continue to

release the pressure bar when the #2-56

screw is already out

of the threaded hole

– try to screw the #2-56 screw back

into the pressure bar for

at least one round.

Over-release the pressure bar will let the

pressure bar fall off

the crystal oven and it

is very difficult to put it back on, without

special tools.

Ordering

Information

●

Crystal

Oven (Specify the exact crystal size to be

hosted, 110V or 220V)

●

Temperature

Controller (Auto detect 110V or 220V)

●

Customized

oven sizes and structures available upon

request, call for price

|

|

|

AOTK紹介ページへ戻る▲

取扱製品一覧へ戻る▲

|

|

|

|