|

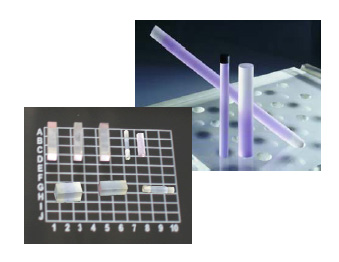

Diffusion

Bonded Composite

Crystals

Diffusion

Bonded Composite

Crystals consist

of one laser

crystal and one

or two undoped

material. They

are combined by

optical contact

method and

further bonded

under high

temperature.

Diffusion Bonded

Crystal helps to

decrease thermal

lensing effect

considerably.

|

|

Advantages

of Diffusion

Bonded Composite

Crystals

●

Decrease

thermal effect

●

Improve

efficiency

●

High

damage threshold

●

Improve

beam quality

●

Compact |

|

Applications

Composite

crystals are used to

effectively decrease

heat effect of

Solid-State

High-Average-Power

Laser. Such products

include YVO4-Nd:YVO4-YVO4,

YAG-Nd:YAG-YAG,

YAG-Nd:YAG-Cr4+:YAG-YAG

crystals, etc.

|

Material

|

Doping

Concentration

|

Aperture

(mm)

|

Length

(mm)

|

|

YVO4+Nd:YVO4+YVO4

|

0.2-3%

|

2x2-10x10

|

3-20

|

|

YVO4+Nd:YVO4+YVO4

|

0.2-3%

|

Φ3-10

|

3-20

|

|

YAG+Nd:YAG+YAG

|

0.5-1.1%

|

2x2-10x10

|

3-200

|

|

YAG+Nd:YAG+YAG

|

0.5-1.1%

|

Φ3-15

|

3-200

|

|

YAG+Nd:YAG+Cr4+:YAG+YAG

|

0.5-1.1%,

T=5-90%

|

Φ3-15

|

3-200

|

We have several assembly

types as follows:

|

Type D

Type F

Type E

For

other assembly type please contact

us for more information.

Standard Specifications

| Wavefront

Distortion |

<

λ/8 at 633 nm |

|

Scattering

Sites

|

invisible,

probed with a He-Ne laser

|

|

Orientation

|

±

0.5deg.

|

|

Dimensional

Tolerance

|

±

0.1mm

|

|

End-faces

Configuration

|

Plano/Plano

|

|

Flatness

|

λ/10

@633 nm

|

|

Parallelism

|

<

10 arc seconds

|

|

Surface

Quality

|

10/5

Scratch/Dig per

MIL-O-13830A

|

|

Clear

Aperture

|

>

Central 90%

|

|

Coatings

|

AR

or HR coatings

|

|